In construction, time is money, and rework is a costly leak in both. Studies show that rework can account for 5% to 15% of total construction costs. That means on a $10 million project, rework alone can burn up to $1.5 million. These aren’t just minor mistakes; they’re missed deadlines, wasted materials, frustrated workers, and unhappy clients.

But there’s good news: companies that prioritize quality control from the very beginning — especially those using robust construction project management software — have reported up to 40% fewer rework instances. That translates into significant savings and smoother project delivery.

In this blog, we’ll explore how quality control processes work, how they reduce costly mistakes, and how you can integrate them into your construction workflow, with or without digital tools.

The Real Cost of Rework in Construction

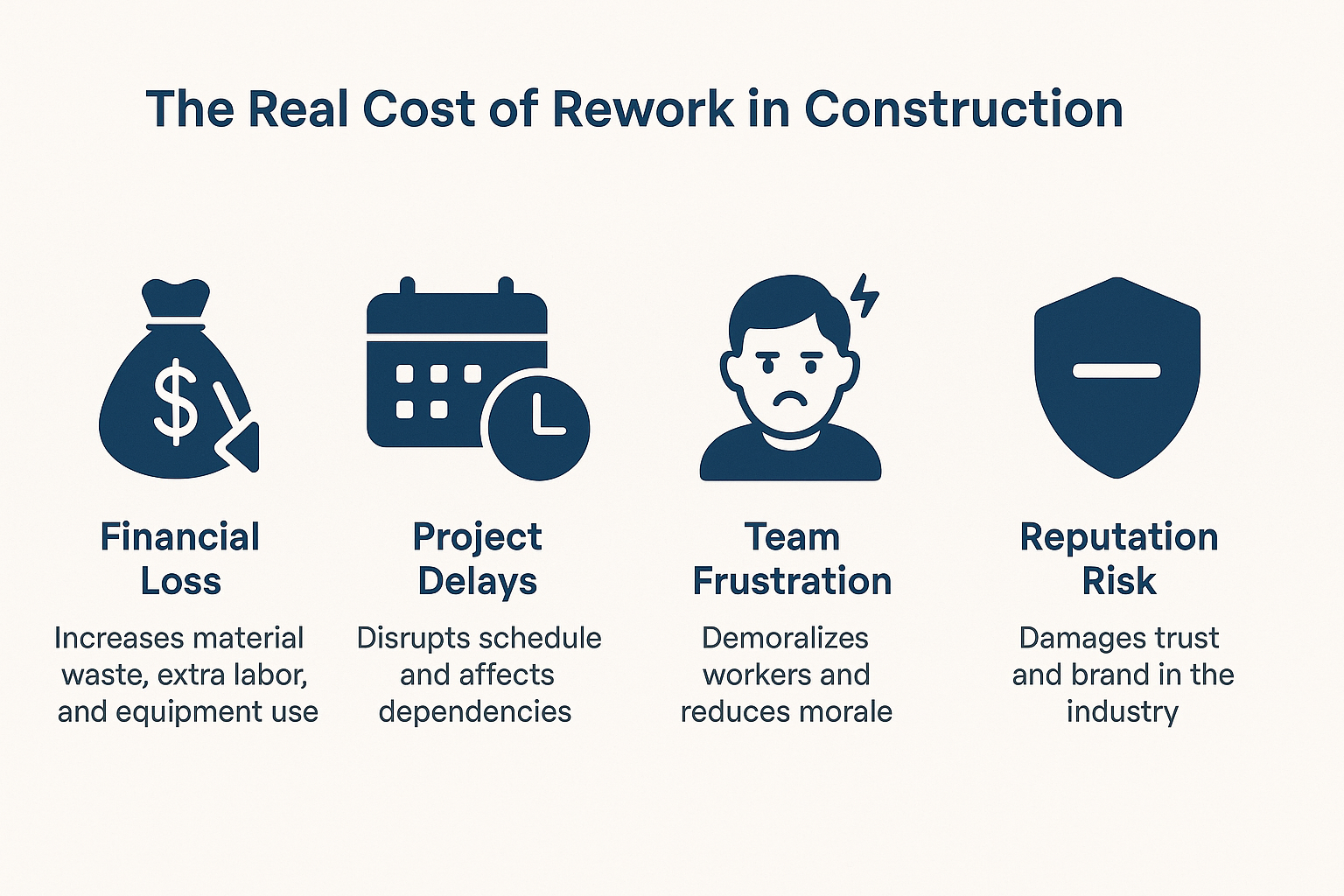

Rework happens when a completed task doesn’t meet quality standards and must be redone. Sometimes it’s as simple as fixing a paint job. Other times, it’s tearing down structural work or reordering expensive components. The consequences go far beyond money.

There’s a direct financial impact — wasted materials, extra labor hours, equipment rentals, and penalties for delays. Then there’s the schedule disruption, as rework ripples through your timeline and affects inspections, dependencies, and resource planning. Lastly, there’s the reputational cost. Teams get demoralized, and clients lose confidence.

The Construction Industry Institute (CII) estimates rework causes over $15 billion in direct costs annually in the U.S. alone. Globally, the cost is even higher, especially in regions where QC processes or project management tools are less standardized.

What Is Quality Control in Construction?

Quality control (QC) in construction refers to the systematic monitoring, inspection, and verification processes used to ensure that all work and materials meet established project standards. It includes every phase of a build, from procurement to foundation to finishing.

Unlike Quality Assurance (QA), which is proactive and process-driven, QC is execution-focused. It involves on-site checks, documentation, supervisor approvals, and immediate corrective actions when issues arise.

When quality control is integrated into your workflow — especially through a digital solution like construction project management software — it becomes a safety net that catches mistakes before they require expensive rework.

How Quality Control Processes Reduce Rework by 40%

A structured QC process is one of the most effective ways to prevent mistakes from becoming money pits. Here’s how:

1. Early Detection Through Structured Checkpoints

Quality control inserts specific checkpoints into every construction phase. For example, before a slab is poured, the team verifies rebar spacing, alignment, and mix quality. These inspections prevent irreversible errors, saving both time and resources.

2. Better Communication and Documentation

When QC processes are digitized using construction project management software, they eliminate guesswork. Everyone — from architects to subcontractors — works off the same checklists, drawings, and specs. That consistency drastically reduces miscommunication-related errors.

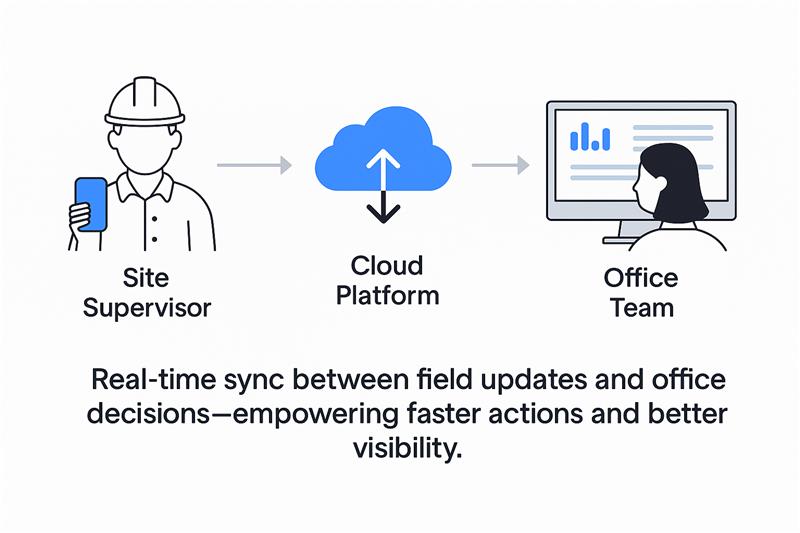

3. Real-Time Tracking of Defects

With digital QC tools, site supervisors can instantly log defects, assign corrective actions, and track resolution. This speeds up the feedback loop and prevents small issues from spiraling into full-scale rework.

4. Built-In Accountability

Each inspection, photo, and approval is documented, making it easier to trace root causes, avoid repeat mistakes, and hold teams accountable. This transparency encourages more attention to detail across the board.

QC Best Practices That Actually Work

Companies that reduce rework consistently don’t just react to problems — they prevent them. Here’s what they do differently:

- Use standardized QC checklists across all job sites, ensuring that every inspection is consistent and thorough.

- Leverage construction project management software to capture quality data in real-time. This eliminates paperwork delays and improves oversight.

- Train subcontractors and workers on quality expectations before they start. Education reduces misalignment and costly surprises.

- Audit quality performance regularly, using reports from your software dashboard to identify repeat problem areas.

When QC is woven into your everyday operations — and supported by the right tools — it transforms from a task into a competitive advantage.

Case Study: Rework Reduced by 40% Using QC + Software

A mid-sized commercial contractor in Bengaluru faced chronic rework issues. Misaligned formwork and concrete curing problems caused delays and ballooned costs, with rework accounting for nearly 7% of the budget.

After adopting OConstruction’s construction project management software, they introduced structured quality checklists, digital inspections, and photo documentation. Supervisors logged and resolved issues in real time, while project managers tracked progress through a central dashboard.

The results were remarkable:

- Rework dropped from 7% to just 3.5%

- The project was completed 17 days ahead of schedule

- Over 85 issues were caught and resolved before the execution

The software-driven QC process didn’t just reduce rework — it improved morale, client satisfaction, and profit margins.

Why Quality Control Is Easier with Construction Project Management Software

Manual QC is time-consuming and inconsistent. But when it’s powered by construction project management software, quality control becomes streamlined and scalable.

With a platform like Oconstruction, you can:

- Create mobile-friendly quality checklists for each task phase

- Log defects and issues with supporting photos

- Set up automated alerts and approvals

- Track corrections and resolutions in real-time

- Generate reports for audits and improvement tracking

Instead of chasing paperwork, your teams stay focused on building — and building it right the first time.

Final Thoughts: Build Right the First Time

Rework eats away at margins, timelines, and team morale. But it’s also preventable. With proactive quality control, backed by the right construction project management software, your company can reduce rework by up to 40%, delivering faster, better, and more profitably.

Don’t wait until mistakes cost you. Build a culture of quality today.

Frequently Asked Questions

Q. What’s the difference between QA and QC in construction?

Ans. QA (Quality Assurance) focuses on processes and planning to avoid defects. QC (Quality Control) focuses on identifying and fixing errors during or after construction work.

Q. Is QC implementation expensive for small firms?

Ans. Not at all. Affordable construction project management software options exist for smaller teams, offering simple QC tools like checklists, logs, and mobile access.

Q. How soon will I see results from better QC?

Ans. Most companies see a drop in rework and faster project delivery within 1–2 project cycles after adopting formal quality control processes and tools.