In the construction industry, communication is more than just exchanging information — it’s the foundation for trust, collaboration, and project success. Whether you’re building residential homes, commercial complexes, or infrastructure projects, how you communicate with clients can make or break the relationship.

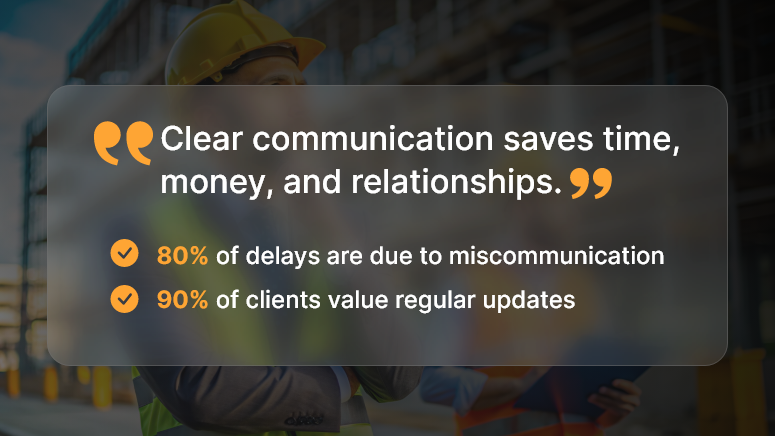

Poor communication can lead to cost overruns, project delays, and disputes, while clear and proactive communication fosters transparency, trust, and smoother project delivery. In this blog, we’ll cover the dos and don’ts of client communication in construction, giving you practical strategies to strengthen relationships and deliver projects with confidence.

Why Communication Matters in Construction

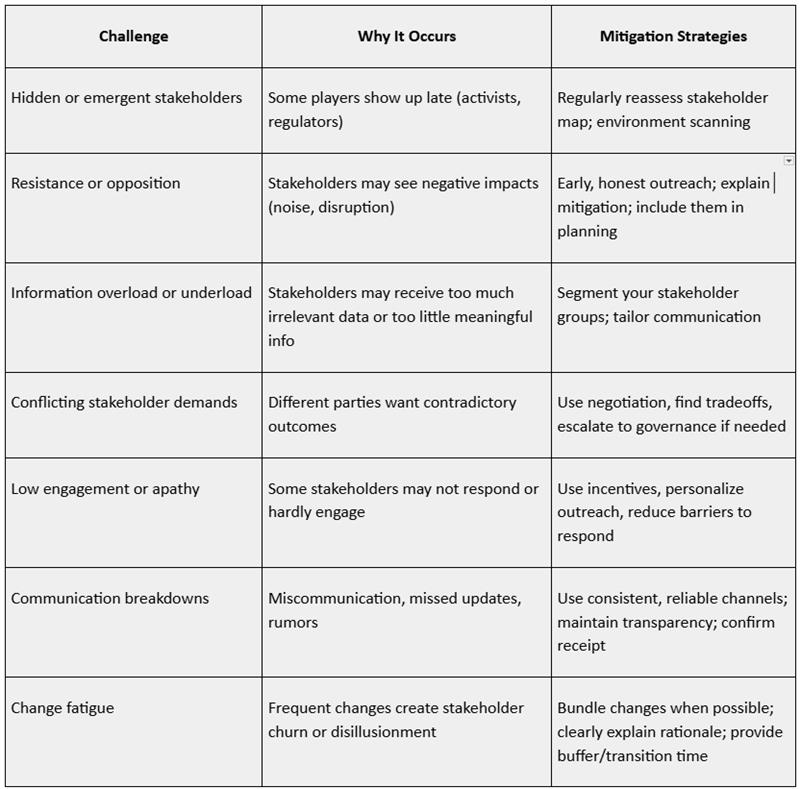

Unlike many other industries, construction involves:

- High financial stakes: Projects represent significant investments for clients.

- Multiple stakeholders: Architects, engineers, contractors, and subcontractors need to stay aligned.

- Uncertainty & risks: Weather conditions, supply chain delays, and design changes are common.

- Long timelines: Communication lapses over months (or years) can cause major misunderstandings.

Strong client communication is therefore not just good practice — it’s essential to managing risk, avoiding disputes, and ensuring client satisfaction.

The Dos of Client Communication

1. Do Set Clear Expectations Early

At the project kickoff, align with your client on timelines, budgets, milestones, and communication protocols. Share a project roadmap and clarify who the client’s primary point of contact will be.

Example: Provide a project calendar that highlights key milestones such as foundation completion, structural work, and finishing stages.

2. Do Listen Actively

Construction clients may not always articulate their needs in technical terms. Listen carefully, ask clarifying questions, and restate what you’ve heard to ensure alignment.

Tip: Use phrases like, “So you’d like the living room to have more natural light — does that mean adding a skylight or larger windows?”

3. Do Use Simple Language

Avoid overloading clients with jargon like “M25 concrete mix” or “cantilevered beam.” Instead, explain in plain English and use visuals (drawings, photos, or 3D models) to make complex concepts easy to grasp.

4. Do Provide Regular Updates

Clients get nervous when they don’t hear from you. Even if everything is on track, schedule weekly or biweekly updates with progress photos and site notes.

Best practice: Create a standard project update template that covers completed tasks, current progress, upcoming milestones, and any issues.

5. Do Document Everything

Verbal instructions can cause disputes later. Always follow up with written documentation—whether it’s a change order, cost adjustment, or design decision. Store these in a central repository accessible to the client.

6. Do Be Transparent About Challenges

Delays, budget overruns, and unforeseen site issues are part of construction. Instead of hiding problems, be upfront with clients. Share the issue, its impact, and proposed solutions. Transparency builds trust, even during setbacks.

7. Do Ask for Feedback Regularly

At each milestone (e.g., foundation, structural work, finishing), ask clients for feedback. This avoids late-stage surprises and ensures their vision is being met.

The Don’ts of Client Communication

1. Don’t Overpromise

Promising an unrealistic completion date or underestimating costs may win approval initially, but it creates disappointment later. Be realistic about timelines and budgets to set achievable expectations.

2. Don’t Hide Problems

Avoid the temptation to delay sharing bad news. Hidden issues (like material shortages or failed inspections) only escalate when ignored. Clients appreciate honesty and proactive problem-solving.

3. Don’t Assume Clients Understand Technicalities

Never assume your client can interpret technical drawings or specifications. Break things down, provide visual aids, and confirm understanding.

4. Don’t Communicate Inconsistently

Random updates and sporadic meetings create confusion. Stick to a structured communication schedule and avoid going silent for long stretches.

5. Don’t Get Defensive in Disputes

When a client raises concerns, don’t react emotionally or defensively. Instead, acknowledge their perspective and provide constructive solutions.

6. Don’t Rely on Informal Channels Alone

While WhatsApp or site chats are convenient, important approvals and change requests should never live only in informal messages. Always back them up with documented agreements.

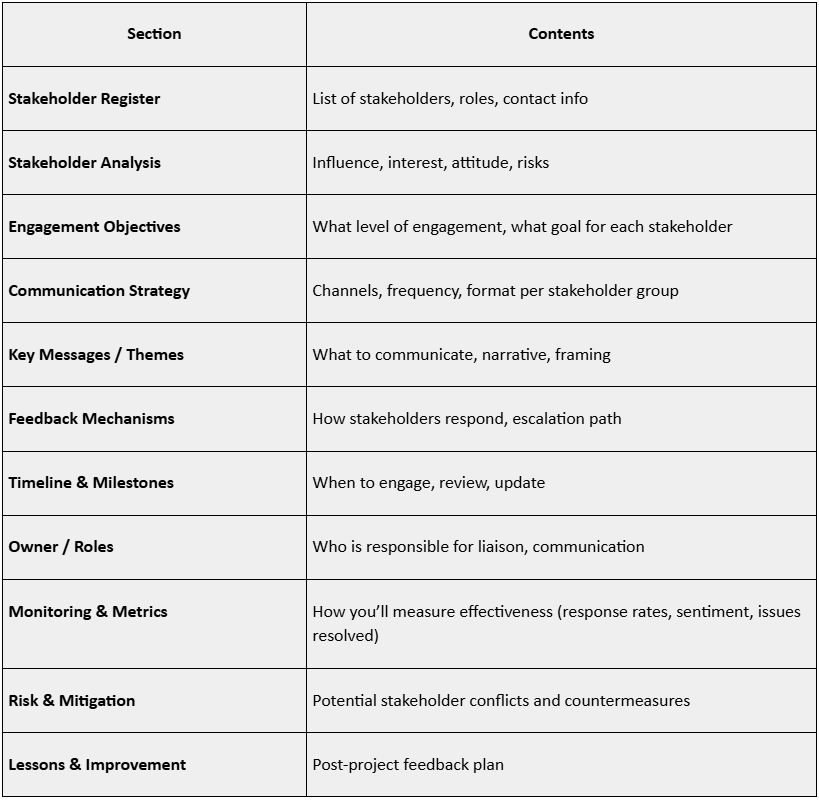

Best Practices for Smooth Communication

- Leverage Technology: Use project management tools (like Procore, Buildertrend, or Orangescrum) to share updates, files, and progress reports in one place.

- Centralize Documentation: Store contracts, designs, and reports in shared folders accessible to clients.

- Use Visual Updates: Photos, progress dashboards, and 3D models make updates clear and engaging.

- Schedule Site Walkthroughs: Invite clients to see progress firsthand at key milestones.

- Train Teams: Ensure all site supervisors and project managers know how to communicate professionally with clients.

Conclusion

Client communication in construction is not just about sharing updates — it’s about building trust, managing expectations, and ensuring successful project delivery.

By following the dos — like setting expectations, listening actively, documenting everything, and being transparent—and avoiding the don’ts — like overpromising, hiding issues, or relying only on informal chats — you can strengthen relationships, reduce risks, and deliver projects more smoothly.

In construction, great communication is as critical as great craftsmanship.

FAQs

1. Why is client communication important in construction?

Construction projects involve high costs, long timelines, and multiple stakeholders. Poor communication can lead to delays, cost overruns, and disputes.

2. How often should clients be updated on construction projects?

Weekly or biweekly updates work best. During critical phases, more frequent updates may be necessary.

3. What’s the best way to deliver bad news to a client?

Be transparent and proactive. Explain the issue, its impact, and provide clear solutions or alternatives.

4. Should communication be formal or informal?

Both have their place. Formal communication (emails, reports, contracts) is essential for documentation. Informal chats (calls, site visits) help build rapport.

5. Which tools help with construction communication?

Tools like Procore, Buildertrend, Orangescrum, and even shared Google Drive or Slack channels can centralize communication and improve transparency.