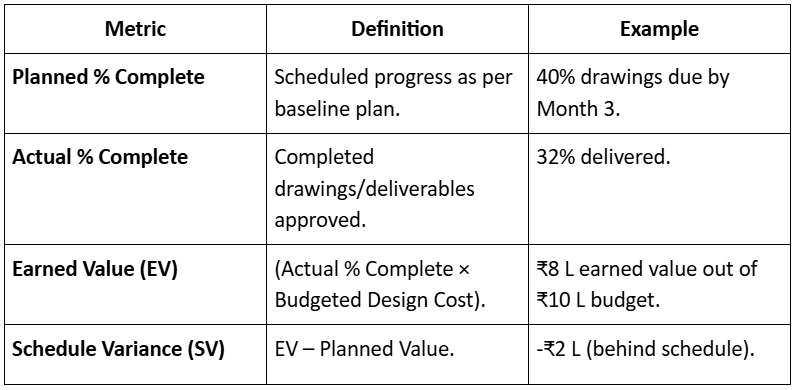

Unlike physical construction, design progress is intangible — measured in deliverables, not cubic meters or tons.

Accurate tracking ensures the timely issue of drawings and prevents construction delays.

1. Design Progress Metrics

2. Tracking Mechanisms

- Maintain a Design Deliverable Register (DDR) listing all drawings, statuses, and approval dates.

- Conduct weekly design coordination meetings.

- Use traffic-light dashboards (Green = on track, Amber = delay risk, Red = critical).

- Integrate design progress into the Master Schedule (MSP/Primavera).

3. Managing Revisions and Change Control

- Log all Revisions (R1, R2, etc.) with reason codes.

- Assess cost and schedule impact before issuing revised drawings.

- Maintain a Change Control Register linking changes to approvals.

Module Summary

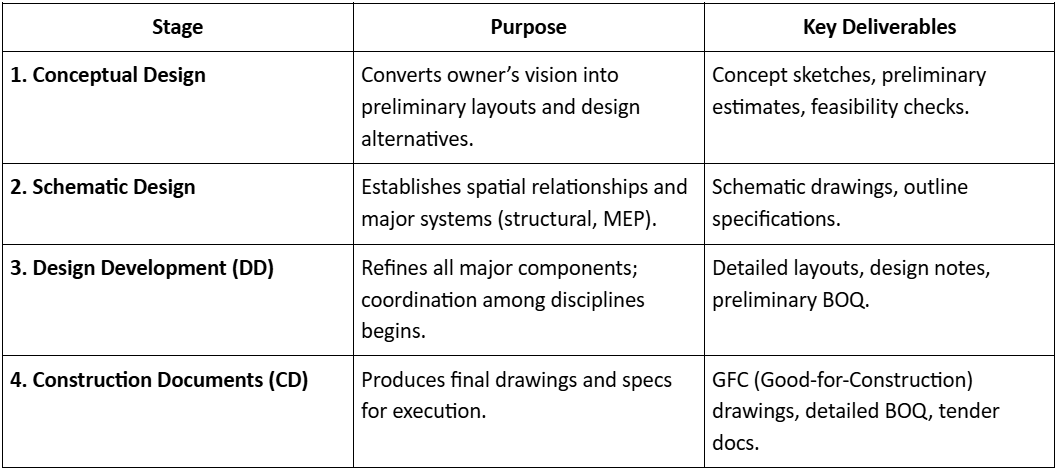

- Design development transforms concepts into executable plans.

- The Project Execution Plan (PEP) governs coordination, cost, and control.

- Mini-drawings simplify reviews and fast-track execution.

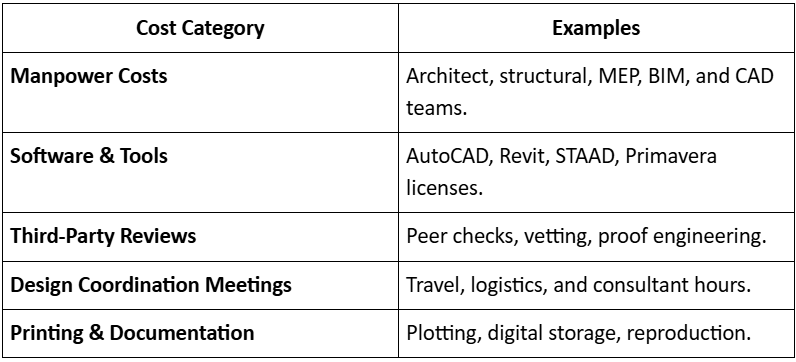

- Proper design budgeting ensures resource efficiency and accountability.

Measuring design progress through EV and DDR prevents downstream delays.