As-built drawings are the definitive records of what was actually constructed — capturing all field modifications and deviations from design.

1. Purpose

- Reflect real installation details and site conditions.

- Aid maintenance, renovation, and future expansion.

- Serve as a legal and technical reference for the owner.

2. As-Built Preparation Process

- Record all changes from construction drawings during execution.

- Mark revisions on drawings (dimensions, routing, material substitutions).

- Validate by an engineer or consultant.

- Digitize and compile into the final drawing set.

- Submit for owner and authority approval.

3. Record Management

- Maintain drawing logs with version and approval history.

- Archive inspection reports, test results, and QA records.

- Prepare a Project Record Book containing:

- Contract documents

- RFIs, NCRs, and MoMs

- Safety and environmental compliance

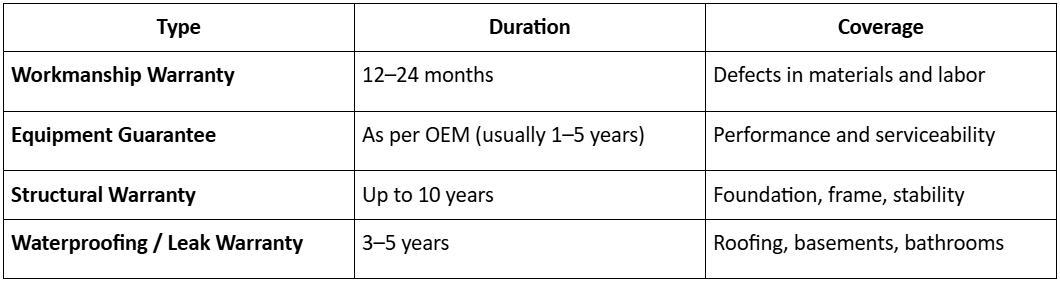

- Certificates and warranties