Scope changes during design are inevitable — but unmanaged changes cause cost escalation, delays, and rework.

1. Common Sources of Design Change

- Client-driven modifications.

- Coordination conflicts (e.g., MEP vs. Structure).

- Regulatory compliance updates.

- Design development refinements.

- Errors or omissions found during peer review.

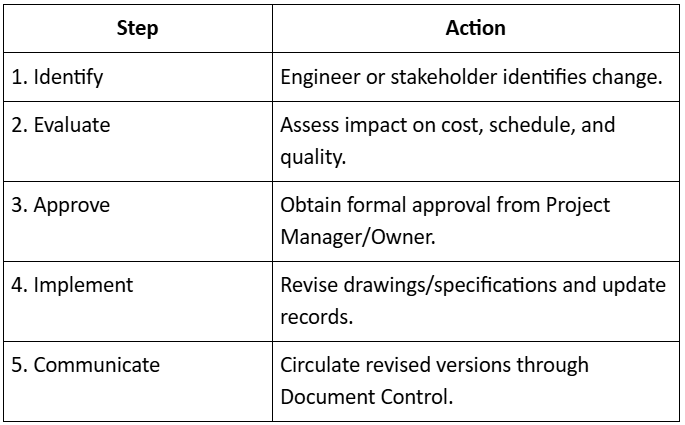

2. Change Control Workflow

3. Tools for Scope Control

- Design Change Register (DCR)

- Request for Information (RFI) logs

- Change Order Forms with justification

- Version History Reports