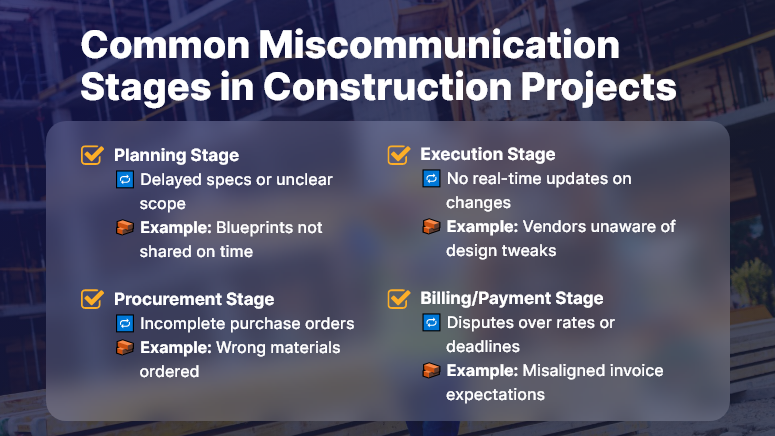

In construction, even one unclear message can create chaos. From material mix-ups to missed deadlines, poor vendor communication is one of the top causes of delays and cost overruns. According to the Project Management Institute, 56% of project failures happen due to bad communication.

That’s a huge problem — but it’s also avoidable.

In this post, we’ll show you exactly how to improve vendor communication across your construction projects. You’ll learn common mistakes, quick wins, and how a digital platform like OConstruction keeps everyone on the same page — from contractors to suppliers.

Why Vendor Communication Matters More Than Ever

Construction projects involve lots of moving parts: internal teams, subcontractors, material vendors, inspectors, and clients. And everyone needs accurate, timely updates — or things fall apart.

When vendor communication breaks down:

- Materials arrive late or at the wrong site

- Subcontractors miss crucial changes

- Deadlines slip, and clients lose confidence

- You waste money fixing problems that didn’t need to happen

So, why should you care?

Better vendor communication means smoother workflows, fewer mistakes, and more predictable outcomes. It also protects your time and budget.

Real Construction Challenges You Can Avoid

- Late steel delivery because the supplier didn’t get the updated schedule

- Wrong insulation was installed because the vendor used an outdated drawing

- Unapproved materials shipped due to misaligned RFQs

With the right communication tools in place, these headaches disappear.

And with OConstruction, you’re not just sending updates — you’re building a system that tracks, confirms, and logs every vendor interaction in one place.

Best Practices to Improve Vendor Communication

Here’s how to get it right — and keep projects moving without confusion.

Centralize All Conversations

- Stop juggling emails, texts, and calls. Use one place for all communication with vendors.

- With OConstruction, you can create shared task threads, tag vendors, and store every file in the cloud — so no one’s ever left out.

Standardize Workflows

Every vendor request should follow a consistent process. Use templates for:

- RFQs

- Change orders

- Delivery instructions

This removes guesswork and ensures clear expectations across the board.

Give Role-Based Access

- Not everyone needs everything. But vendors do need access to key documents, schedules, and status updates.

- OConstruction lets you control what each vendor can see — ensuring clarity and data security.

Automate Notifications

- Schedule changes? Approvals? Due dates?

- Set up auto-notifications inside your construction platform. Vendors get real-time alerts, reducing the chance they’ll miss critical updates.

Track Every Change

- Verbal updates fade. Written logs last.

- Use digital records with timestamps to track who said what — and when.

- This creates accountability and prevents finger-pointing later.

Don’t Leave Vendors Out of the Loop

- You might think your internal team has it handled. But vendors are partners — and they need to be part of the conversation.

- Make sure they know about updates as they happen, not after.

Don’t Assume They Read Every Email

- Emails get buried. Attachments get missed.

- Use built-in task comments, tagging, and push notifications to make sure vendors see what you send.

OConstruction Makes It Easy

With OConstruction, you can:

- Set up shared vendor workspaces

- Create task threads with comments

- Use version-controlled documents

- Automate alerts and due date reminders

- Provide mobile access for field and vendor use

Everything happens in one place — reducing noise, avoiding confusion, and saving time.

Customer Story: Clear Communication That Delivered Results

For example, Hardline BuildCo, a regional construction firm, used OConstruction’s vendor access tools to streamline coordination with 8 suppliers and 10 subcontractors.

Before using the platform, they struggled with delayed materials and missed delivery windows — costing them thousands each month.

After switching:

- On-time deliveries increased by 60%

- Vendor-related errors dropped by 70%

- Project managers gained back 10+ hours a week

“With OConstruction, we finally had visibility and structure in our vendor communication,” said the company’s Senior PM.

Key Takeaways

- Vendor communication is essential to project success — yet often overlooked

- Poor communication leads to delays, rework, and missed deadlines

Using tools like OConstruction, you can:

- Centralize updates

- Track every interaction

- Standardize workflows

- Keep vendors aligned in real time

Clear communication isn’t just a productivity booster — it’s a risk reducer. By proactively keeping vendors in the loop and using digital tools to document every step, you minimize costly errors and maximize efficiency. With the right systems in place, your vendor relationships become stronger, your timelines more predictable, and your projects more profitable.